-

Products

-

Civil Engineering Testing Instruments

-

Material Testing Equipment

-

Transducer & Data loggerStrain Gauge

- General Use

- Waterproof

- High Temperature Use

- High and low temperature

- Cryogenic temperature use

- Weldable

- Concrete Material Use

- High Endurance

- For Plastic

- Wood, Gypsum Use

- For Magnetic Field

- Post-yield

- bending and tensile

- Stress Gauge

- Temperature

- Crack Detection

- Bolt Strain

- Sensor specific

- Strain Gage Related Products

- Load Cell

- Displacement

- Pressure

- Velocity/ Acceleration

- Stress

- Torque

- Temperature

- Tilt

- Water Content

- Pore Water Pressure

- Inertial Measurement Unit

- Static Strain Gauge Data Logger

- Dynamic Strain Transducer Data Logger

- Static Strainmeter

- Dynamic Strainmeter

- Portable Strainmeter

- Slope Movement Monitoring

- Strain Indicator

- Strain Gauge Calibration

- Frictional Type Torque Sensor

- Slip-ring type Wheel Torque Measurement

- Slip-ring type Wheel Force Transducer

- Vehicle Examination Transducer

-

Teaching and Research Laboratory EquipmentFluid Mechanics Advanced Fluid Mechanics Fluid Machine Thermodynamics Heat Transfer Renewable Energy Refrigeration & Air Conditioning Chemical Engineering Unit Operations Biochemical Engineering Water Treatment Applied Hydraulics & Hydrology Educational Food Technology Irrigation Water Management Internal Combustion Engine Process Control Teaching System Statics & Vibrations Fluid Science Engineering Fundamentals Machine Elements Naval Architecture

-

Digital Platform

-

Industrial Testing

-

Environmental Testing

-

Mobile impact crusher

-

Device Diagnostic Tool

-

-

Industry

-

Roads, Bridges, Airports, and Railways Engineering

-

Building and Infrastructure

-

- Solution

- Service

- News

- Community

- About

-

Products

-

Civil Engineering Testing Instruments

-

Material Testing Equipment

-

Transducer & Data loggerStrain Gauge

- General Use

- Waterproof

- High Temperature Use

- High and low temperature

- Cryogenic temperature use

- Weldable

- Concrete Material Use

- High Endurance

- For Plastic

- Wood, Gypsum Use

- For Magnetic Field

- Post-yield

- bending and tensile

- Stress Gauge

- Temperature

- Crack Detection

- Bolt Strain

- Sensor specific

- Strain Gage Related Products

- Load Cell

- Displacement

- Pressure

- Velocity/ Acceleration

- Stress

- Torque

- Temperature

- Tilt

- Water Content

- Pore Water Pressure

- Inertial Measurement Unit

- Static Strain Gauge Data Logger

- Dynamic Strain Transducer Data Logger

- Static Strainmeter

- Dynamic Strainmeter

- Portable Strainmeter

- Slope Movement Monitoring

- Strain Indicator

- Strain Gauge Calibration

- Frictional Type Torque Sensor

- Slip-ring type Wheel Torque Measurement

- Slip-ring type Wheel Force Transducer

- Vehicle Examination Transducer

-

Teaching and Research Laboratory EquipmentFluid Mechanics Advanced Fluid Mechanics Fluid Machine Thermodynamics Heat Transfer Renewable Energy Refrigeration & Air Conditioning Chemical Engineering Unit Operations Biochemical Engineering Water Treatment Applied Hydraulics & Hydrology Educational Food Technology Irrigation Water Management Internal Combustion Engine Process Control Teaching System Statics & Vibrations Fluid Science Engineering Fundamentals Machine Elements Naval Architecture

-

Digital Platform

-

Industrial Testing

-

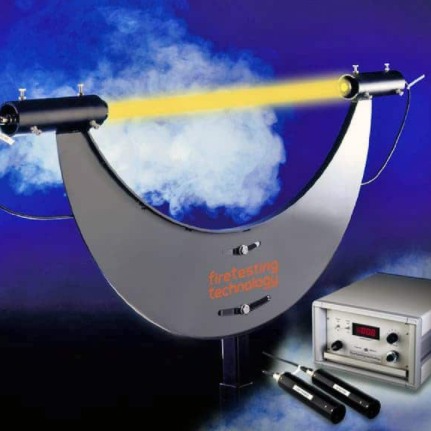

Environmental Testing

-

Mobile impact crusher

-

Device Diagnostic Tool

-

-

Industry

-

Roads, Bridges, Airports, and Railways Engineering

-

Building and Infrastructure

-

-

-

-

-

- Solution

- Service

- News

- Community

- About

- 購買

- 中文

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717