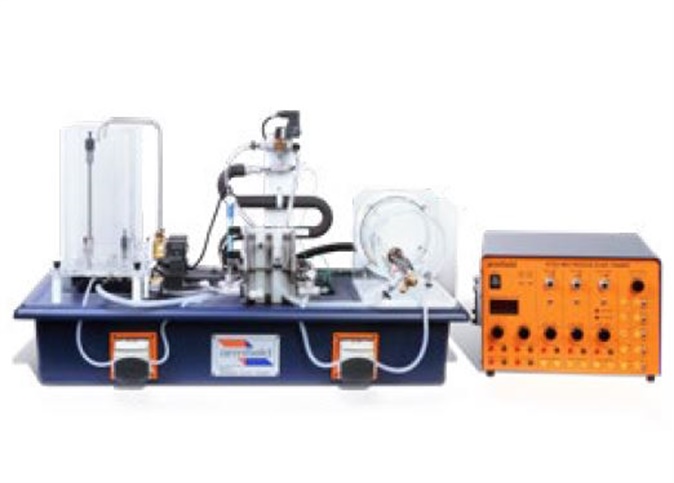

The Armfield Process Plant Trainer – PCT23MKII can be used to demonstrate a complete range of process control methods and strategies. Manual control and single feedback loops through to sophisticated cascade loops can be demonstrated along with distributed supervisory control of the whole process, by a remotely located computer.

The system is a miniature replication of a true production process. The student is presented with real process control problems with realistic dynamic behaviour and instabilities.

EXPERIMENTAL CONTENT – PCT23

Practical training exercises

The Armfield PCT23MKII Process Plant trainer is designed to cover course topics ranging from a first introduction to the subject of process control through to demonstrations of the latest advanced techniques including the use of online mathematical models.

Plant Monitoring using a PC – Gaining familiarity with computer-based mimic diagrams for monitoring process variables: level, temperatures, flows and power.

Calibration of Sensors – To calibrate the level sensor installed on the Process Plant Trainer.

Process Dynamics I

-

Steady State Operation (Direct Heating) – Introducing a first order system and the achievement of steady state by investigating the hot water tank characteristics (observing the effect of constant direct heating on the temperature in the hot water tank)

-

Indirect Heat Exchange – Demonstrating indirect heating using a plate heat exchanger

-

Dead Time – Demonstration of the phenomenon of dead time

-

Step Changes – Measuring the response of a system (the plate heat exchanger) to step changes

-

Heat Transfer Losses – To calculate heat transfer losses for the system

Process Dynamics II

-

Interaction – Demonstrating the interaction between different loops in the system.Understanding how changing one process variable (e.g. flow rate) affects all the others (eg. temperatures)

-

Heat Regeneration – From both environmental and economic viewpoints, recycling or regeneration of energy within the process is desirable. The heat exchanger on PCT23 is equipped with a regeneration section where incoming cold feed is preheated by outgoing hot product

-

Indirect Cooling – In some situations, the finished product will need to be cooled further for final storage even after giving up energy in the regeneration section of the heat exchanger. The heat exchanger on PCT23 is equipped with a cooling section where outgoing roduct can be indirectly cooled using cold water (or chilled water)

-

Process Duty – Understanding process duty and temperature differentials in the heat exchanger

-

PID Control of Level using Software – Introduction to level control using a PC (single loop PID controller in software)

-

PID Control of Flow using Software – Introduction to flow control using a PC (single loop PID controller in software)

-

PID Control of Temperature using Software – Introduction to temperature control using a PC (single loop PID controller in software)

-

PID Control of Conductivity using Software -To control the conductivity of the final product by adding a salt solution to the feed

-

Indirect PID Control of Temperature – To demonstrate single loop PID control

-

PID Control of Temperature with Dead Time – To demonstrate single loop PID control, with product temperature controlling heater power

-

PID Control with Alarm Driven Disturbances – To demonstrate the effect on control action of including an alarm-activated diverter valve

-

Controller Optimisation – Determining the ideal control parameters for a simple system (single loop, temperature to heater power)

-

Controller Optimisation with Dead Time – Determining the ideal control parameters for a simple system with dead time (single loop, temperature to heater power)

-

Two Loop Cascade Control – To demonstrate cascade control, whereby product temperature controls hot water temperature set point, which in turn controls heater power

-

Two Loop Control and Interaction – To demonstrate the effect on process response of two separate PID control loops which interact

-

Three Loop Control – To demonstrate multivariable control with interacting and non-interacting loops

-

Fault Finding and Diagnostics – Fault simulation and diagnosis by the instructor switching out selected signals

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk  Whatsapp Enquiry: +85261990717

Whatsapp Enquiry: +85261990717